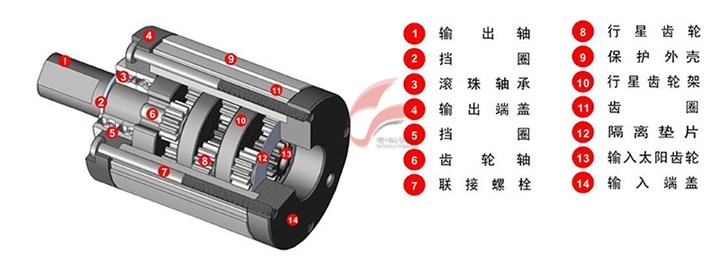

Principle of planetary reducer: The drive source (motor) starts the sun gear in a direct connection, and the sun gear drives the planetary gears combined on the planetary gear carrier to run. The whole group of planetary gear system rotates automatically along the outer gear ring, and the planet carrier is connected to the output shaft to achieve the purpose of acceleration. Higher reduction ratios need to be multiplied and accumulated by multiple sets of stage gears and planetary gears.

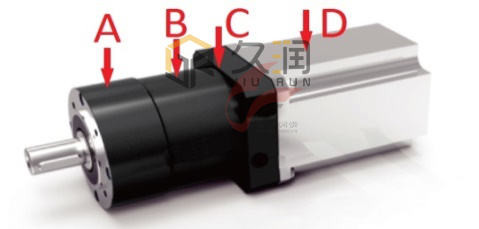

Structural features: compact structure, good heat exchange, high precision, high transmission efficiency, strong applicability, maintenance-free for life

Application fields: mechanical deceleration device for process equipment in many industries and fields such as metallurgy, mining, transportation, water conservancy, chemical industry, food, beverage, textile, tobacco, packaging, environmental protection and so on.

Components Composition:

The requirements of the planetary reducer for grease:

Wear resistance: reduce wear and temperature rise, meet the needs of lifelong lubrication of the reducer

Noise reduction: improve product comfort

Adhesion performance: maintains a uniform oil film on metal surfaces, reducing wear and noise

Mechanical stability: prevent the oil from softening after shearing and oil leakage

High and low temperature performance: reduced low temperature starting torque and high temperature softening under high load conditions

The company's solutions for planetary gearboxes:

Our company uses a unique polyurea thickener, refined synthetic oil, and a special type of extreme pressure anti-wear agent, which has good high and low temperature performance, low starting torque at low temperature, no coking at high temperature, and good shearing performance , Under the condition of high temperature and extreme pressure, the structure is not easy to be damaged, the structure is stable, and it has good adhesion to the metal surface.

Main Specifications:

Project | Quality Index | Measured value | Test Standard | |

Exterior | Beige Evening Ointment | Beige Evening Ointment | Visual inspection | |

Operating temperature range(℃) | -30~200 | -30~200 | — | |

Penetration 1/10mm | - | 285-315 | ASTM D217 | |

NLGI grade | 1.5 | 1.5 | ASTM D217 | |

Dropping point °C | >260 | - | ASTM D2265 | |

Steel mesh oil separation 24h 100℃ | <5.0% | - | ASTM D6184 | |

Evaporation loss 1h 120℃ | <5.0% | - | SH/T0337 | |

Water splash test 60min 40℃ | <5.0% | - | ASTM D1264 | |

45# steel corrosion 3h 100℃ | Qualified | Qualified | ASTM D4048 | |

Four ball wear marks 1200r/min 1h 75℃ 40KG | - | 0.452mm | ASTM D2266 | |

Four ball test PD 1500r/min 10s | - | 600 | ASTM D2596 | |

Low temperature torque(-40℃)mN.m | start up run 10min run 60min | - - - | 110 50 - |

ASTM D1478 |

Antioxidant properties 100h、100℃ | - | - | ASTM D942 | |

Rust test 24h、52℃ | Qualified | Qualified | ASTM D1743 | |

(The above data is for reference only and does not have the nature of a contract.)

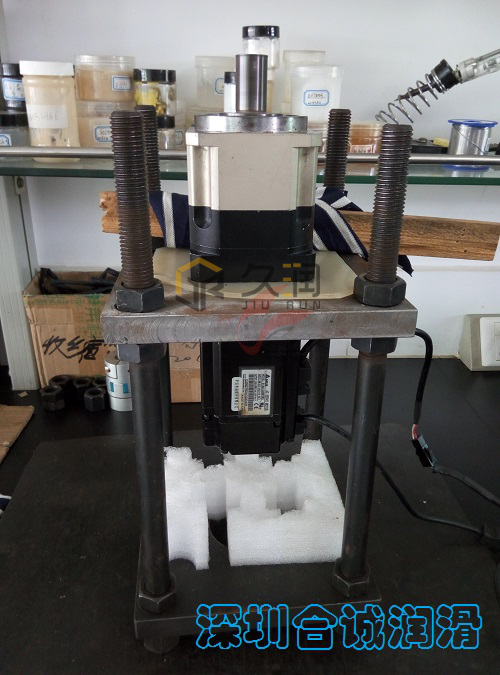

Test product | Helical gear planetary reducer, spur gear planetary reducer (*Kai 80 type first class) |

Test Equipment | Decibel meter, infrared thermometer, servo motor |

Grease model | FAKKT-MG33002 |

Test site | Building 4, Taiwei Industrial Zone, No. 146, Yanluo Road, Yanchuan, Songgang, Baoan, Shenzhen (bench laboratory) |

Testing requirements:

1.Temperature rise≤75℃,

2.Noise≤65Db,

3.The oil film on the tooth surface is intact

Test process: reducer type: helical gear (grease amount: 25g)

Oil film condition

Reducer type: straight tooth (grease amount: 20g)

Oil film condition

Test Results:

Judging from the test records, using the FAKKT-MG33002 grease test, the two toothed planetary reducers have good temperature rise, noise and oil film conditions, meeting the manufacturer's requirements.

Please fill in your message, we will reply as soon as possible!